Materials (Basel). 2017 Sep 5;10(9). pii: E1040. doi: 10.3390/ma10091040.

Abstract

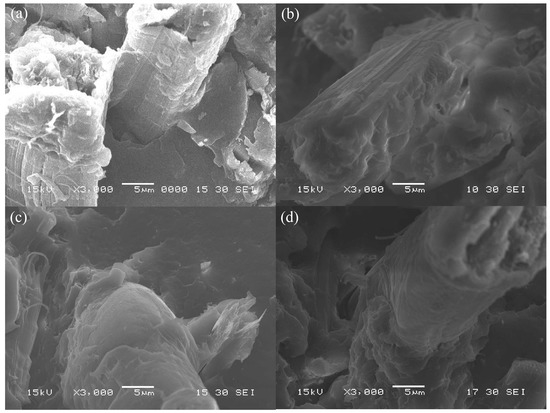

We have studied the effects of silane coupling agents used for the surface treatment of fiber on the tribological properties of hempfiber (HF) reinforced plant-derived polyamide 1010 (PA1010) biomass composites. Hemp fibers were surface-treated by two surface treatment methods: (a) alkali treatment by sodium hydroxide solution and (b) surface treatment by silane coupling agents. Three types of silane coupling agents, namely aminosilane, epoxysilane and ureidosilane were used. These HF/PA1010 biomass composites were extruded using a twin extruder, and injection-molded. The mechanical and tribological properties were evaluated by the ring-on-plate type sliding wear test. It was found that tribological properties of HF/PA1010 biomass composites improved with the surface treatment by the silane coupling agent. This may be attributed to the change in the mode of friction and wear mechanism by the interfacial adhesion between fiber and matrix polymer according to the type of silane coupling agent used. In particular, the ureidosilane coupling agent showed the best improvement effect for the tribological properties of these biomass composites in this study.

We have studied the effects of silane coupling agents used for the surface treatment of fiber on the tribological properties of hempfiber (HF) reinforced plant-derived polyamide 1010 (PA1010) biomass composites. Hemp fibers were surface-treated by two surface treatment methods: (a) alkali treatment by sodium hydroxide solution and (b) surface treatment by silane coupling agents. Three types of silane coupling agents, namely aminosilane, epoxysilane and ureidosilane were used. These HF/PA1010 biomass composites were extruded using a twin extruder, and injection-molded. The mechanical and tribological properties were evaluated by the ring-on-plate type sliding wear test. It was found that tribological properties of HF/PA1010 biomass composites improved with the surface treatment by the silane coupling agent. This may be attributed to the change in the mode of friction and wear mechanism by the interfacial adhesion between fiber and matrix polymer according to the type of silane coupling agent used. In particular, the ureidosilane coupling agent showed the best improvement effect for the tribological properties of these biomass composites in this study.▼ Figures

KEYWORDS:

friction; hemp fiber; plant-derived polyamide; polymer-matrix composites; silane coupling agent; wear

- PMID: 28872624

- DOI: 10.3390/ma10091040

-

Conflict of interest statement

The authors declare no conflict of interest.